A carbonator pump is a device that infuses carbon dioxide gas under high pressure into a liquid, thus creating bubbles that make the liquid effervescent.

Here’s a summary of the content you will find on this page:

• How do carbonator pumps work

• Carbonation pumps applications

Before delving into carbonator pumps and their functioning, let’s find out what carbonation is.

Carbonation is a process that occurs when carbon dioxide reacts to a liquid – in this case, water – and dissolves into it creating bubbles.

Water is composed of molecules in constant motion, a movement that increases and decreases concurrently with temperature. These molecules attract each other, but there is a space or void between them in which carbon dioxide gas is entrained.

Consequently, exposing any water surface to this gas entails gas absorption into the water.

But when a given volume of water absorbs the maximum quantity of gas, it means that the liquid has reached its saturation point. If water is saturated, it cannot absorb any more CO2 unless gas pressure is increased or water temperature is decreased.

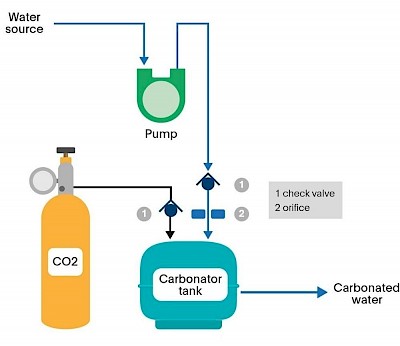

There are various methods to carbonate water, but the main one involves a carbonator pump equipped with a closed stainless steel tank – with a high/low-level switch that operates the motor.

In the case of these carbonator pumps, compressed carbon dioxide gas is conveyed into the steel tank, where water pressure gets boosted in order to overcome CO2 pressure and be channeled through an orifice restriction. This orifice converts the energy of the pressure into a jet of water that travels into the steel tank, allowing the two elements to come into contact.

Finally, CO2 dissolves into the liquid inside the carbonation tank, thus forming bubbles and resulting in effervescent water.

At first, only the upper layer of water exposed to the gas is carbonated. But to effectively carbonate the whole quantity of water needed, water must be exposed to a higher amount of time to the gas. In order to reduce the required time, the surface area exposed to the gas must be increased.

Liquid temperature is also a key factor, because of what is stated by the kinetic theory of gases: higher temperatures increase the motion of water molecules, which accelerates the performance of the carbonator pump and the absorption of the gas into the liquid.

Carbonator pumps are mainly used in fields requiring hot and cold fluids to be precisely pressurized, dispensed, and dosed.

Their main application concerns food service, where these pumps are used both to carbonate beverages but also to maintain the carbonation level throughout the dosing and circulation phases.

Carbonator pumps, in fact, produce water that can be used as a beverage itself or as a base to add flavor to other drinks.

According to the destination of use required, you may find an ambient or cold carbonation pump, but it can also be stand-alone or integrated into the dispenser.

Fluid-o-Tech is a leading manufacturer of carbonator pumps for the food service industry, where water and beverages need an effervescent taste.

We are able to produce and provide carbonation pumps that guarantee easy use, safety, long durability, and great efficiency. Their high innovative level is fundamental to optimizing performance both for commercial and industrial purposes.

Among the other advantages of our carbonator pumps with sensors, they guarantee:

• Real-time adjustment

• Compactness and lightweight

• Customizable options, according to your needs

• Serial interface

For further information please fill out the form below

For any information feel free to contact us and a Fluid-o-Tech representative will contact you

CONTACT