Cooling Pumps for "Thermal Management" Systems: General Overview

This article aims to provide an overview of thermal management systems with a particular focus on the role that pumping systems and valves play in these types of systems.

Below is a brief summary:

• Applications of a battery cooling pump

• How does a cooling pump work

• Fluid-o-Tech cooling pumps for Thermal Management

Thermal management refers to energetically optimizing the thermal balance in a vehicle. A thermal management system involves controlling temperature through technology. This technology is based on thermodynamics and heat transfer.

Thermal management is a wide-ranging term covering various forms of heat transfer, including conduction, convection, and radiation, involving different processes.

In the automotive industry, thermal management is necessary for protecting and insulating batteries. Battery cooling system's performance is crucial for BEV, HEV, PHEV, and FCEV vehicles, a proper design of the cooling system can provide real answers to key challenges related to:

• Durability of battery

• Vehicle performance

• Fast recharging

• Range

Here are some of the application fields of a battery cooling pump within advanced systems with new hydraulic requirements:

• heat transfer from battery cell/module to coolant, heat transfer within the system, heat sink

• solutions for better heat transfer from battery to coolant:

a) immersive cooling with dielectric coolant & different viscosity

b) improved geometry in cooling plates

c) higher flow rate in the system to increase heat transfer from source to sink

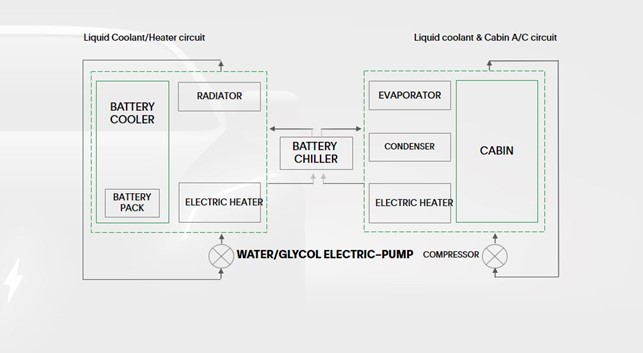

d) “Coolant on Demand Strategy” connecting coolant and refrigerant systems

High temperatures are produced during the combustion of the engine cylinder. This causes the heat to be released in the vehicle, in the environment, or to be absorbed by the engine – thus leading to damage.

Electronic cooling pumps are specifically made to regulate the temperature in a certain limited space. In the case of motor vehicles, these pumps are needed to prevent them from overheating. You might find two types of systems they support:

• HVAC (air cooling) systems

• water cooling systems (Read also: Water Injection Pumps)

These last ones work with a cooling liquid, a mix of water, glycol, and other additives that

• capture the heat

• move it around a closed circuit

• cool it down

• release it again

Electronic cooling pumps are able to operate even after the engine has been stopped. They can be installed externally or on the crankcase.

Read also: Coolant Pump

Cooling pumps for thermal management and for EV fast charging are vital components to supply coolant on-demand for critical thermal management systems. Heat control can be very consuming in terms of power and fuel, but there are several approaches to reduce consumption and let the battery of the cooling pumps work efficiently.

By cooling the engine precisely and only as required, in fact, cooling pumps reduce fuel consumption with the additional benefit of curbing friction losses and emissions.

When selecting an EV thermal management pump that can be relied upon, it's important to consider the limitations of traditional water pumps, such as centrifugal pumps, which are often constrained by a single BOP. With the growing demand for features like "Coolant on Demand" and "Fast Charging" in electric vehicles, there is a need for multiple coolant circuits, which could lead to an increase in the number of traditional pumps used. However, a more efficient solution like Positive Displacement pumps can significantly reduce the number of EV thermal management pumps required, offering a more streamlined and effective approach to managing the thermal needs of electric vehicles.

The future could be represented by the technology of positive displacement volumetric pumps which could play a better role as electronic cooling pumps for these systems.

These pumps, in fact, offer the following main advantages:

• Robust design

• High Efficiency

• Suitable for high-pressure and high flow

• Low Noise

• Tolerant to abrasive particles

• Easy assembly

• Multiple BOP (Best Operating Point) due to a variable speed

New-generation electric vehicles will employ increasingly complex systems. Fluid-o-Tech with more than 70 years of experience, competencies, products, its advanced R&D department, and simulation center is the right partner to develop future thermal management systems.

Our Fluid-o-Tech team has developed innovative solutions that satisfy Customer’s needs while respecting all environmental regulations.

Fluid-o-Tech cooling pumps are designed to fit multiple architectures (Passenger Vehicles, Buses, Trucks, Heavy Duty, and Commercial Vehicles) showing our ability to create tailored solutions for our Customers, focusing on integration always directed to the edge of the technology.

For further information please fill out the form below

For any information feel free to contact us and a Fluid-o-Tech representative will contact you

CONTACT