Discover on this page various aspects of hydrogen pumps, starting from their definition and operation, exploring the different types available and their operating mechanism. Take a look also at the numerous applications and benefits of these pumps, with a particular focus on the innovative solutions offered by Fluid-o-Tech, a leader in the field.

On this page, we will see:

• What about hydrogen heat pump

Hydrogen pumps are used in systems that convert hydrogen-rich liquids into hydrogen gas. These systems allow the hydrogen to be converted into other forms of energy, a procedure that is growing constantly as it represents a sustainable alternative with reduced environmental impact.

Tranforming hydrogen into energy typically requires pumping a hydrogen rich fuel stock, such as a mixture of methanol and deionized water, which is then transformed into a purified hydrogen gas through specific processes. The hydrogen pumps play a fundamental role in powering the flow of the fuel stock into the hydrogen generator systems.

There are several types of hydrogen pumps, each suitable for specific needs and processes. Here is an overview of the main types:

• Gear Pump: Gear pumps are commonally used as they are very accurate, robust, offering a long life and able to operate with challenging pressure requirements. The pumps are simple in operation, offering precise metered flowrate with varying conditions. Flowrates can be controlled depending on the varying quantity of hydrogen required for the application. Gear pumps provide an optimal choice for performance and long-term reliability in this challenging environment

• Rotary Vane Pumps: Rotary vane pumps are another popular choice for transporting hydrogen. These pumps utilize vanes that rotate inside a chamber, creating fluid movement. Known for their ability to maintain a uniform and stable flow, even under variable pressure conditions, these pumps are suitable for a wide range of applications.

• Centrifugal Pumps: Centrifugal pumps use rotary motion to create centrifugal force that moves the fluid. They are particularly effective in applications where a large flow rate is required, such as in large-scale electrolysis processes.

Learn more about our hydrogen pumps!

Hydrogen generators produce high-purity hydrogen through methods such as Steam Methane Reforming (SMR) and electrolysis:

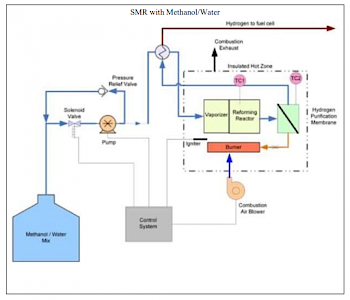

• The Steam Methane Reforming (SMR) process uses methane-rich materials, such as natural gas, and reacts with steam to produce hydrogen gas and carbon dioxide, along with other elements. The resultant hydrogen gas is then purified with membrane technologies, achieving high purity needed for energy conversion. There is also a variant of this process that uses a mixture of methanol and water, using a vaporizer instead of steam to produce the hydrogen gas without as much impurities.

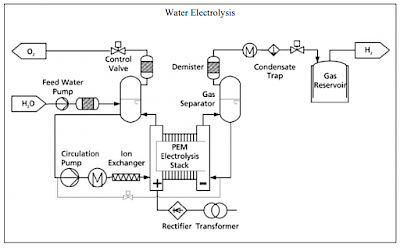

• Electrolysis uses electric current to separate hydrogen from oxygen in water, using an electrolyzer with an anode and cathode. This process produces almost contaminant-free hydrogen, making it one of the cleanest methods to generate this element.

Both processes, SMR and electrolysis, offer different approaches to hydrogen production, with unique strengths and specific challenges related to purity, energy efficiency, and environmental impact.

Hydrogen pumps are widely used in various industrial sectors, especially for:

• Powering industrial vehicles

• Generating backup energy

• Powering off-grid systems

• Handling methane

In addition to being very versatile, these pumps are also particularly advantageous for other reasons, as they ensure:

• Reversible operation

• Stable flow rate

• Reduced energy consumption

• Compact design

• Low noise

A hydrogen heat pump uses hydrogen as a medium to transfer thermal energy from one source to a destination, for heating or cooling purposes. This type of heat pump offers a sustainable solution for heating and cooling buildings, as well as for producing hot water. Here are some of the key uses and benefits:

• Sustainable Heating - with its ability to utilize hydrogen, a clean and renewable resource, the hydrogen heat pump represents an eco-friendly alternative to traditional heating systems that rely on fossil fuels.

• Energy Efficiency - these heat pumps are highly energy-efficient, capable of producing more heat than the electrical energy consumed. This makes them a cost-effective choice for long-term heating and cooling.

• Versatility - they can be used not only for heating spaces but also for cooling during warmer months, in addition to producing domestic hot water, thus offering a comprehensive solution for both residential and industrial needs.

• CO2 Emission Reduction - using hydrogen as an energy source significantly contributes to reducing greenhouse gas emissions, aligning with global decarbonization goals and efforts to combat climate change.

• Integration with Renewable Energies - hydrogen heat pumps can be easily integrated with other systems based on renewable sources, such as solar photovoltaic or wind energy, further optimizing the energy efficiency and environmental impact of the building.

Fluid-o-Tech, a leader in pump manufacturing, stands out for producing cutting-edge solutions.

Our pumps are developed to ensure optimal performance even under high pressures and boast extended durability.

We offer a range of competitively priced products, adaptable to the specific needs of the customer, including the possibility of customizing pumps. Our customer-oriented approach and advanced engineering expertise allow us to respond effectively to OEM requests.

We are distinguished by continuous innovation, excellent resistance, and solid experience in the field, making us a trusted partner for your hydrogen pumping solutions.

Create your hydrogen pumps with us!

For further information please fill out the form below

For any information feel free to contact us and a Fluid-o-Tech representative will contact you

CONTACT